In the early half of November 2021 there were 111 cargo vessels waiting near California’s southern coast to be docked so that consumer goods could get unloaded and shipped onward. The situation has since improved, as the number of waiting ships has been nearly cut in half. In spite of this improvement in the supply chain flow of goods, businesses and consumers alike will likely continue to experience delays and shortages as we head into the holiday season.

Here, we’ll explain some of the contributing factors to and consequences of supply chain bottlenecks as well as how your company can optimize its supply chain management.

Related: What is Supply Chain Management (SCM)?

Acute stressors that exploit existing supply chain weak points

The COVID-19 pandemic and cyber attacks are two major contributing factors to existing and complex supply chain problems in the US. Resulting consumer fears and perception of scarcity lead to stockpiling which only exacerbates supply chain bottlenecks.

COVID-19 pandemic

Broader supply chain disruptions are no doubt connected to the ongoing pandemic. For many companies, existing weak points in the supply chain, such as decentralized data, data duplication, and lack of automation, have become especially apparent during the pandemic.

The average worldwide cost of shipping a container has more than quadrupled since last year. In addition, the fees for unmoved containers at the dock are going up as well, but due to related rail and trucking bottlenecks, companies are essentially paying exorbitant storage fees for their containers that have nowhere to go. These increased shipping and storage prices cause businesses to choose between going out of business or passing the costs onto the consumer through higher product prices.

Coupled with backend pain points in the supply chain, consumer demand has increased, putting even more pressure on companies to better plan how they get their product out as quickly as possible. With eased restrictions throughout the country and more widespread vaccine availability, consumer spending in the US is rebounding. While companies saw a lull in product demand in early to mid 2020, they’ve been struggling to keep up since demand began ramping up in summer 2020. Consumers are not only buying again, but they’re also overbuying out of anxiety surrounding store supply, thus exacerbating supply chain disruption. Toilet paper and hand sanitizer, for example, were particularly hot items in 2020.

Read also: 5 Ways to Repair Your Supply Chain

Cyber Warfare

Cyber attacks on supply chain networks underscore the importance of security in SCM.

In May 2021 the Colonial Pipeline, a major oil supplier to the US east coast became the target of a ransomware attack. As news of the attack and subsequent pipeline shutdown hit major media outlets, consumers rushed to gas stations which only made the oil supply problem worse. The reduction in supply in conjunction with panic buying of gasoline led to some gas station closures and a jump in the national average price per gallon, especially throughout the affected regions.

Companies are particularly vulnerable to attacks on their software supply chain for two main reasons. For starters, third-party software products usually require privileged access. In addition, many of these products require frequent communication between the vendor and customer networks, with the vendor’s software acting as an intermediary. Malicious actors can intercept and intervene in channels of communication between vendor and customer.

The takeaway here is twofold. Do not accept a third-party software’s default access settings, as this allows potential entry points for bad actors. Also, implement a cybersecurity supply chain risk management (SCRM) strategy, such as the Software Bill of Materials (SBoM) approach. As part of your strategy, choose a SCM software, such as Infor M3, that takes security seriously and deploys regular security updates.

Read also: Colonial Pipeline Ransomware Attack Shows Critical Infrastructure Vulnerabilities

Planning gets you far, SCM software gets you further

Companies can and should anticipate cyber threats, but no business owner could have predicted the COVID-10 public health crisis and its far-reaching effects on the supply chain. Nevertheless, companies that invest time, money, and resources into SCM strategy and software weather crises better than those that do not plan ahead.

Read next: Key Benefits of an Optimized Supply Chain

There are actionable steps your company can and should take to implement, if not improve, its supply chain management by using the right software and/or tools. Start by assessing which SCM tool is right for your company’s needs. A crucial, and perhaps the most labor-intensive, step in supply chain optimization is mapping. Below are a number of factors in the supply chain mapping process that various software and tools can aid with.

Read next: The Best Supply Chain Management Software & Tools

Supply chain mapping

Start by identifying your top five revenue-generating products. Map out your supply chain for those products, from raw material to end product. The map will give you greater visibility into your company’s supply chain and will help you identify vulnerable spots to take further action on. Mapping is easier said than done and will take a significant amount of time and resources but will ultimately fortify your company against future unpredictable situations.

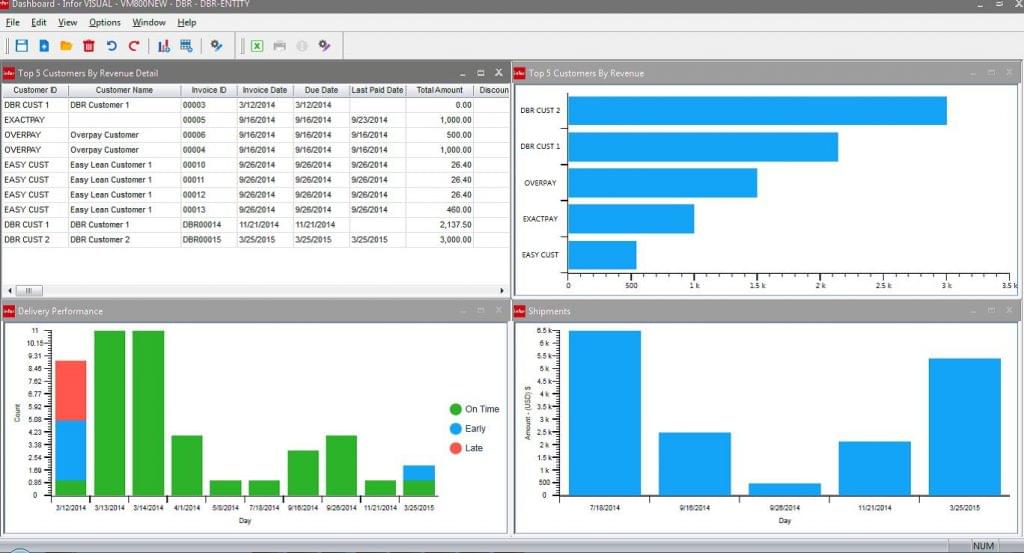

For this step, it will be crucial to have all your data in one place. Alloy, for example, not only allows visibility into how SCM works with other vital functions of the company, such as production, but it also shows real-time, end-to-end data from point-of-sale up through the supply chain. Infor VISUAL is a scalable ERP solution that helps identify bottlenecks and boost scheduling efficiency through data visualization of steps in the production process and how they all fit together.

It takes a village: cross-functional collaboration

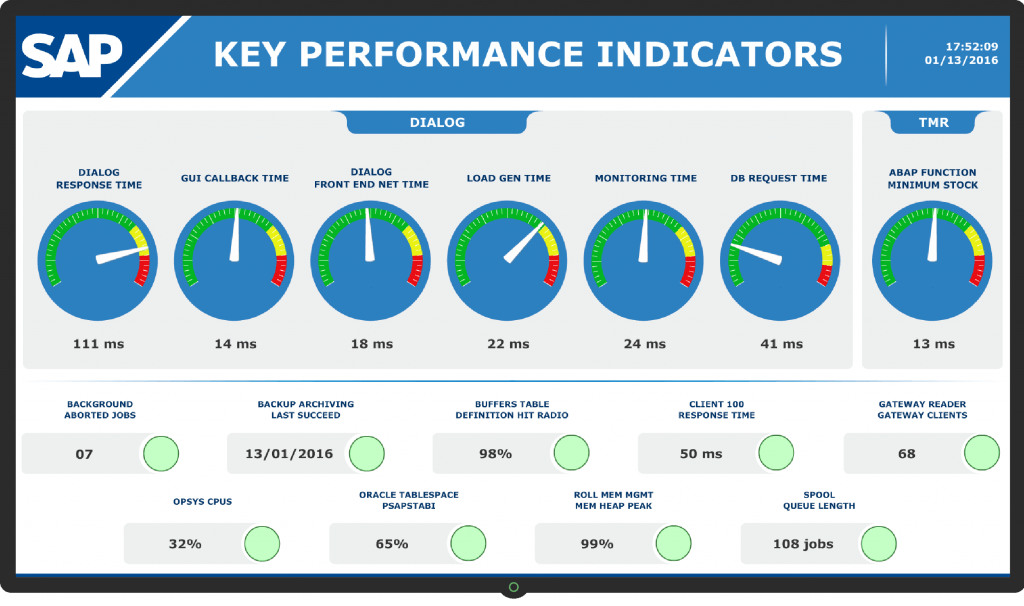

Relevant stakeholders from procurement, logistics, and supply chain finance need to be in conversation with one another about identifying vulnerabilities in the supply chain as well as ways to patch them up. SAP SCM, E2Open, or Oracle SCM facilitate buyer-supplier collaboration.

Make friends with suppliers…and their suppliers

Identify not just one, but a few key suppliers of raw materials at every step of the chain. Rank those suppliers from most reliable and cost-efficient to least, so that you have several back-up plans on hand. Moreover, learn what locations they’re operating in and who their suppliers are.

Get suppliers onboard with mapping efforts

Mapping the supply chain is not an internal endeavor. Instead, it should include external stakeholders, like your suppliers. When deciding on suppliers to work with, make joint supply-chain planning a part of your contract. Identify methods to address potential disruptions and the estimated time it will take to do so. Supply chain optimization is only as good as the buy-in you get from suppliers.

Security against uninvited links to the chain

The Colonial Pipeline ransomware attack is a telling example of why security in the supply chain is critical to ensuring that your company can adapt to unforeseen challenges. Though a company cannot always predict when and how a cybersecurity attack will occur, there are still plenty of ways it can prepare and try to mitigate such risks. Fortinet offers supply chain security solutions for manufacturing and operations technology-based environments. For supply chain security in the DevOps setting, ActiveState and Tanzu are two software supply chain security solutions that ensure end-to-end protection within the software development lifecycle.

Why SCM software is crucial

You can’t account for unforeseen circumstances, but you can be proactive. Implementing SCM and choosing the right SCM software solution will take considerable time and financial investment. Yet, running a lean yet adaptable company will be beneficial in the long-term. Benefits include lower costs, more efficiency, customer satisfaction, and many more. These benefits far outweigh the costs of being reactive. Check out the TechnologyAdvice Guide to Supply Chain Management Solutions to learn more about what matters in a SCM solution.