Key takeaways

- Streamlining and optimizing your work order process for efficiency is essential for remaining profitable and competitive.

- We recommend performing these seven audits on your work order process to optimize efficiency, reduce risks, and keep customers coming back.

For field service and maintenance industries, poor work order management can lead to execution delays, reduced reliability, and unachievable service agreements. Your work order process directly impacts customer satisfaction. If your response times are slow or the process is unorganized, the customer suffers, and you could potentially lose business.

Where do customers go when they’re displeased with a service? Yelp. A survey conducted by Dimensional Research found that 86-percent of service customers would pay more for a residential service provider with higher ratings and reviews. A bad service experience may not only lose you that customer, but also future customers who frequent review pages.

Streamlining and optimizing your work order process for efficiency is essential for remaining profitable and competitive. We recommend performing these seven audits on your work order process to optimize efficiency, reduce risks, and keep customers coming back.

ALSO READ: 3 Ways to Use Current Data to Improve Field Service Outcomes

In this article...

Recommendations for a better work order process

1. Design, document, and implement a standardized process

Without a standardized process in place for all stages of the work order process (initiation, submission, scheduling, working, verification, and invoicing), no one is on the same page about when to submit a work order request, the level of detail that should be on it, and what job-related expenses should be recorded. Needing a “fast response time” on a work order could mean four hours to one worker and four days to another.

As a company, identify what kind of tasks require creating a work order, what is critical to include in the initial work order, and what information should be included on the work order during the working stage.

It’s helpful to establish templates, protocols, and benchmarks to remove the guesswork from the equation and set expectations. Protocols hold all technicians to the same standard, making sure that work is uniform across the board. Work order maintenance templates lowers the probability of error and/or confusion while providing consistency across all work orders. Benchmarks allow a company to set the expectation on responsiveness. Setting clear expectations about when a work order should be completed will cut down response time discrepancies.

2. Switch to a digital format

Post-it notes, white boards, and assigning work via phone calls becomes inefficient and messy quickly. A paper-based format relies heavily on technicians to coordinate work between themselves and makes it near impossible to discover any insight into how the process could be done better.

Even full reliance on spreadsheets causes problems with managing user rights and billing and invoicing. Switching from a paper-based to a digital system makes it easier to adhere to work order best practices and increases productivity. A digitized work order system will take all of the components within a work order, initiation, submission, scheduling, etc., and consolidate them into a centralized system that’s easy to access and view for multiple parties.

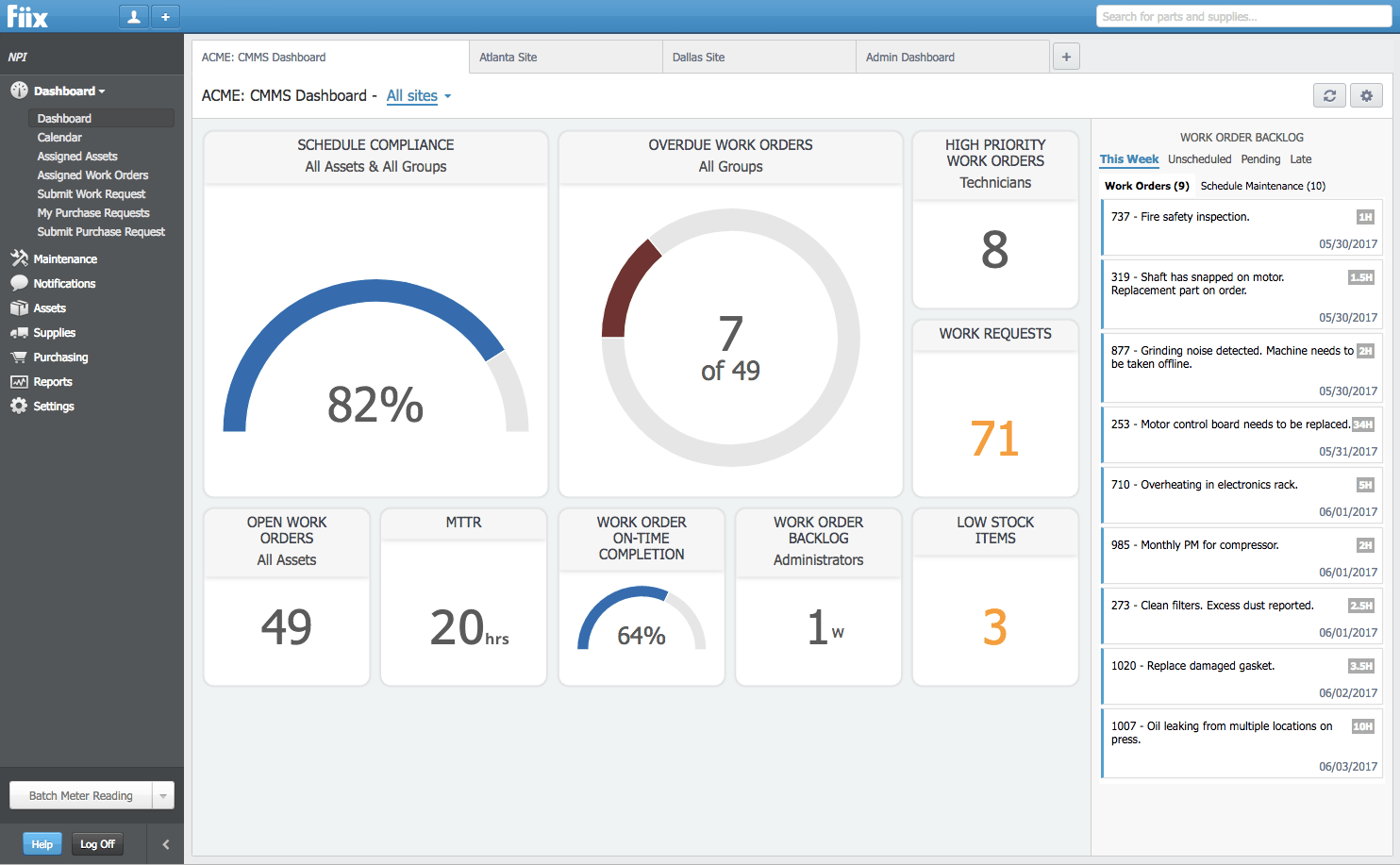

Investing in a CMMS or FMS such as Fiix that has work order automation capabilities will allow you to create, organize, track, complete, and analyze work order requests in one place. Create work orders with mandatory fields that can be prioritized, filtered, and assigned instead of using paper work orders and risking human error. Add manuals, pictures, and checklists to the work order, and create scheduled triggers to automatically generate work orders for recurring preventive maintenance.

3. Match your work order process to the customer journey process

We’ve all experienced that slightly annoyed feeling when a company gives us a broad 4-hour window of when their technician could appear. And we’ve all experienced the frustration when that technician doesn’t appear within that time frame. 36-percent of customers won’t rehire a technician if they’re over 30 minutes late, and it’s possible the customer could leave a poor review.

Generating positive customer reviews will accelerate your business by bringing in word-of-mouth (or word-of-internet) customers. To do that, your work order design should be flexible enough to allow for customer preference. Consider the customer journey alongside the work order process to get a good idea of what the customer is experiencing and where their pain points are.

In your company’s work order process, what is your customer experiencing when you’re scheduling and assigning a job? They’re probably wondering when their technician will arrive and what level of expertise he or she has. They expect the technician to arrive when they say they will, and your work order process should function to achieve that. Align the unique needs of your business to the customer’s journey to understand how you can better serve them.

4. Prioritize work orders

At any given moment, your company has multiple work orders to address, and it likely would not be the smartest move to respond to work orders as they come in. A system of triage needs to be implemented to ensure peak customer satisfaction. Fixing a light bulb and fixing an HVAC unit in the middle of winter should have different levels of prioritization.

Make sure you’ve implemented a prioritization system to categorize your work orders by urgency. While the majority of your work orders will be “medium” priority, there should be a hierarchy that differentiates when something is urgent. Software such as IndusTrack will allow you to assign priorities to jobs as high, medium, or low. To help in determining priority, assess the likelihood and timeline of failure and the consequences.

5. Implement an approvals process

Implementing an approval process for a work order before physical works ever begins allows you to catch any possible errors before they happen. Approval should be contingent on all required information being clearly and accurately completed, the budget being accurate, and no safety concerns needing to be addressed.

6. Make use of reporting and analytics

One of the biggest advantages of housing your work order process in a software is being able to make use of the analytics it provides. Important metrics to track include:

- What is the most common work order request?

- How long do the most common work orders take to fix?

- What is the recurrence rate of particular work orders?

- How well is your communication flow working?

These metrics will allow you to see what needs improvement, increasing not only customer satisfaction but also employee satisfaction.

CMMS software such as UpKeep will allow companies to see how much they’re spending and the time it takes to complete a work order. Important reports include a status report, work order analysis, maintenance compliance, work order aging, and time and cost.

7. Use work orders for even the smallest tasks

While it may seem like more work on the front end, using a work order for even the smallest of tasks will keep your company accountable for all tasks and be able to troubleshoot issues in the future because everything is documented. Even tasks that seem irrelevant adds up to hours across your team’s time spent.

Looking for the latest in FSM solutions? Check out our Field Service Management Software guide.